UNO AIR's News

2025-07-14

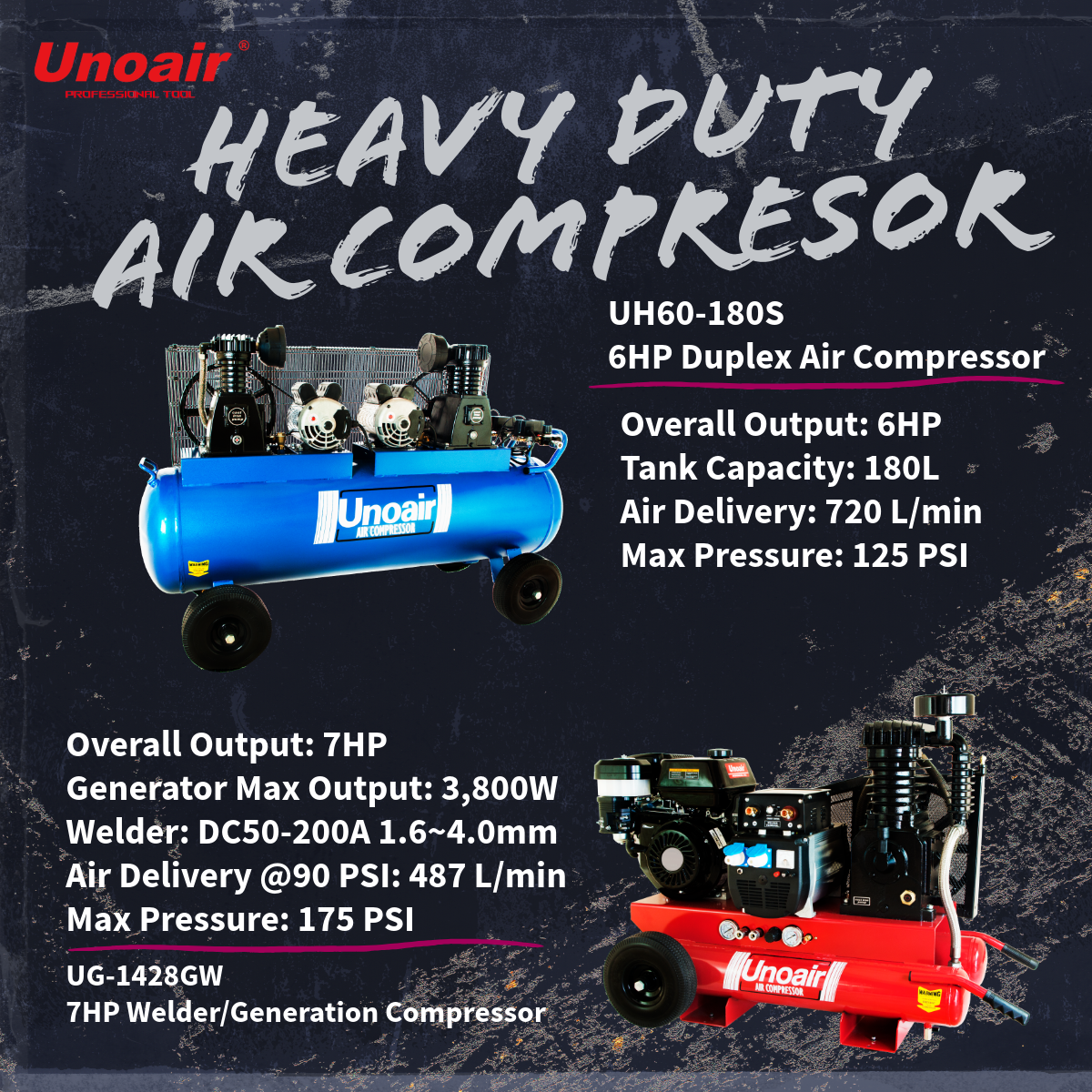

The deplux air compressor helps you save energy and extend the life of your compressor by intelligently managing power usage.

It lets you choose whether to use both pumps simultaneously or switch to a single pump when you need less air.

It’s designed for optimal efficiency.

2025-07-02

A pneumatic rivet shaver is a specialized air-powered tool used to smooth or shave the heads of rivets so they are flush with the surrounding surface—typically on metal structures.

What it does:

After a rivet is installed, its head may protrude slightly. A pneumatic rivet shaver removes that excess metal to create a flat, smooth finish, which is important for:

-Aerodynamics (e.g., in aircraft structures)

-Aesthetic appearance

-Safety and structural integrity

Common uses:

-Aerospace industry (airplanes, helicopters)

-Automotive repair

-Shipbuilding and metal fabrication

-Any project requiring flush rivet finishes

2025-06-25

Your one-stop partner for air compressors and air tools.

2025-06-18

Keeping your air compressor cool in a hot environment is crucial for performance, safety, and longevity.

Here are some effective tips:

1. Ensure Proper Ventilation

Place the compressor in a well-ventilated area to allow hot air to escape and cool air to circulate.

Use exhaust fans or ventilation ducts to remove hot air from the compressor room.

2. Use External Cooling Fans or Blowers

Add industrial fans or portable blowers aimed directly at the compressor to help dissipate heat, especially around the motor and pump.

3. Avoid Direct Sunlight

If installed outdoors or near windows, make sure the compressor is shaded or in an enclosed space that shields it from the sun.

UV-resistant covers can also help protect and cool the unit.

4. Use an Aftercooler or Intercooler

Aftercoolers remove heat from compressed air, reducing the overall temperature of the system.

Some high-performance setups include intercoolers between compression stages.

5. Keep Filters and Fins Clean

Dust, dirt, and grime reduce heat dissipation. Clean intake filters, cooling fins, and fans regularly to maintain airflow.

Clogged air filters also force the compressor to work harder, generating more heat.

6. Check and Maintain Lubrication

Use high-temperature compressor oil in hot climates.

Regularly check oil levels and change the oil based on the manufacturer's recommendation to reduce friction and overheating.

7. Reduce Duty Cycle

Avoid running the compressor continuously for long periods.

If possible, increase tank size or use multiple compressors to share the load.

8. Monitor Temperature Sensors

Install a thermal overload switch or temperature sensor to automatically shut off the unit if it overheats.

2025-06-11

World-class, top-tier pneumatic tools at competitive prices, with flexible minimum order quantities and outstanding after-sales service.

2025-06-04

An air compressor system converts power into compressed air, which is then stored and used to power tools, machinery, and equipment. Its main purpose is to provide a reliable source of energy for applications like inflation, cleaning, painting, automation, and powering pneumatic tools in both industrial and home settings.

2025-05-21

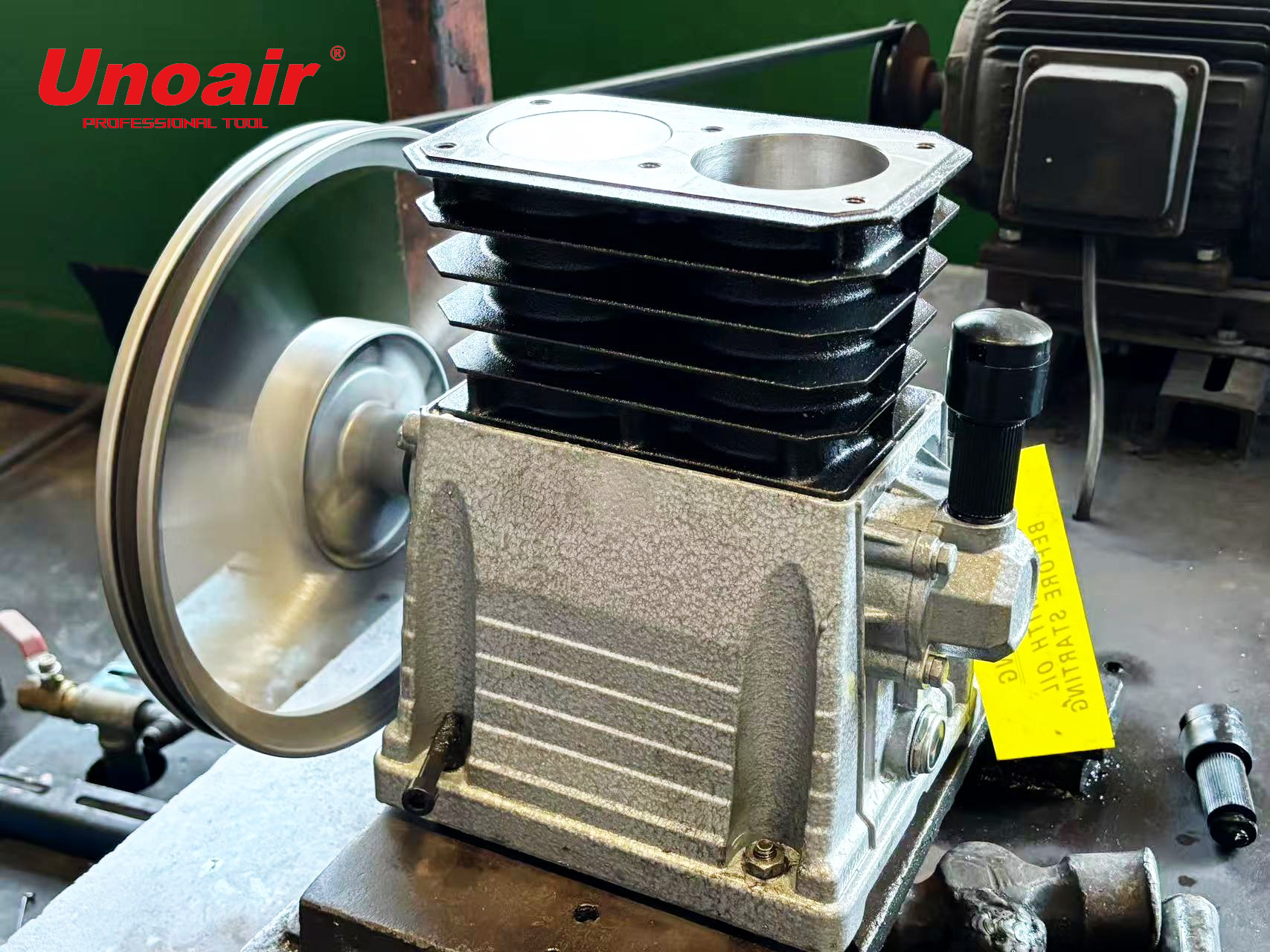

Today, we conducted a pump test for a customer from Japan. The pump is engineered to operate continuously for hundreds of hours without rest, and any oil leakage or abnormal behavior is regarded as a failure. While the standard test cycle consists of a 3-minute run followed by a 2-minute rest, our method pushes the pump to its maximum tolerance. A successful result is a strong indicator of the pump’s quality.

2025-05-14

An air compressor with welder and generator is a multi-function machine commonly used in construction, repair, and maintenance settings. It combines three essential tools into one unit:

1. Air Compressor

Purpose: Powers pneumatic tools like impact wrenches, nail guns, paint sprayers, and air chisels.

Use Cases: Auto shops, construction sites, metalworking.

2. Welder

Purpose: Enables arc welding for joining metal parts.

Use Cases: Fabrication, equipment repair, metal structure assembly.

3. Generator

Purpose: Produces electrical power for tools, lights, and equipment when no external power is available.

Use Cases: Remote job sites, power outages, mobile service vehicles.

2025-05-07

A pneumatic bead seater is special because it solves a common and frustrating problem in tire installation: getting the tire bead to seal quickly and securely against the rim, especially when dealing with tubeless tires.

Here’s what makes it stand out:

*Instant High-Volume Air Delivery

Unlike a standard air compressor that fills slowly, a bead seater delivers a sudden, high-volume blast of air. This rapid pressure pushes the tire sidewalls outward, seating the bead in one go.

*Essential for Difficult Tires

It’s especially useful for:

Large or stiff tires (e.g., trucks, ATVs, tractors)

Old or dry rubber that doesn’t flex easily

Aftermarket or non-standard rims that don’t match tire curvature perfectly

*Saves Time and Effort

Without one, you might spend time trying to coax the bead into place using ratchet straps, soapy water, or repeated inflations.

A bead seater gets the job done in seconds, improving efficiency in garages or roadside service.

*Portable and Easy to Use

Most pneumatic bead seaters are portable tanks that can be refilled with an air compressor, making them ideal for field use or mobile tire services.

2025-04-30

The purpose of filters used on air compressors and air tools is to ensure clean, dry, and contaminant-free compressed air, which is essential for optimal performance, safety, and longevity of both the compressor and the connected equipment.