UNO AIR's News

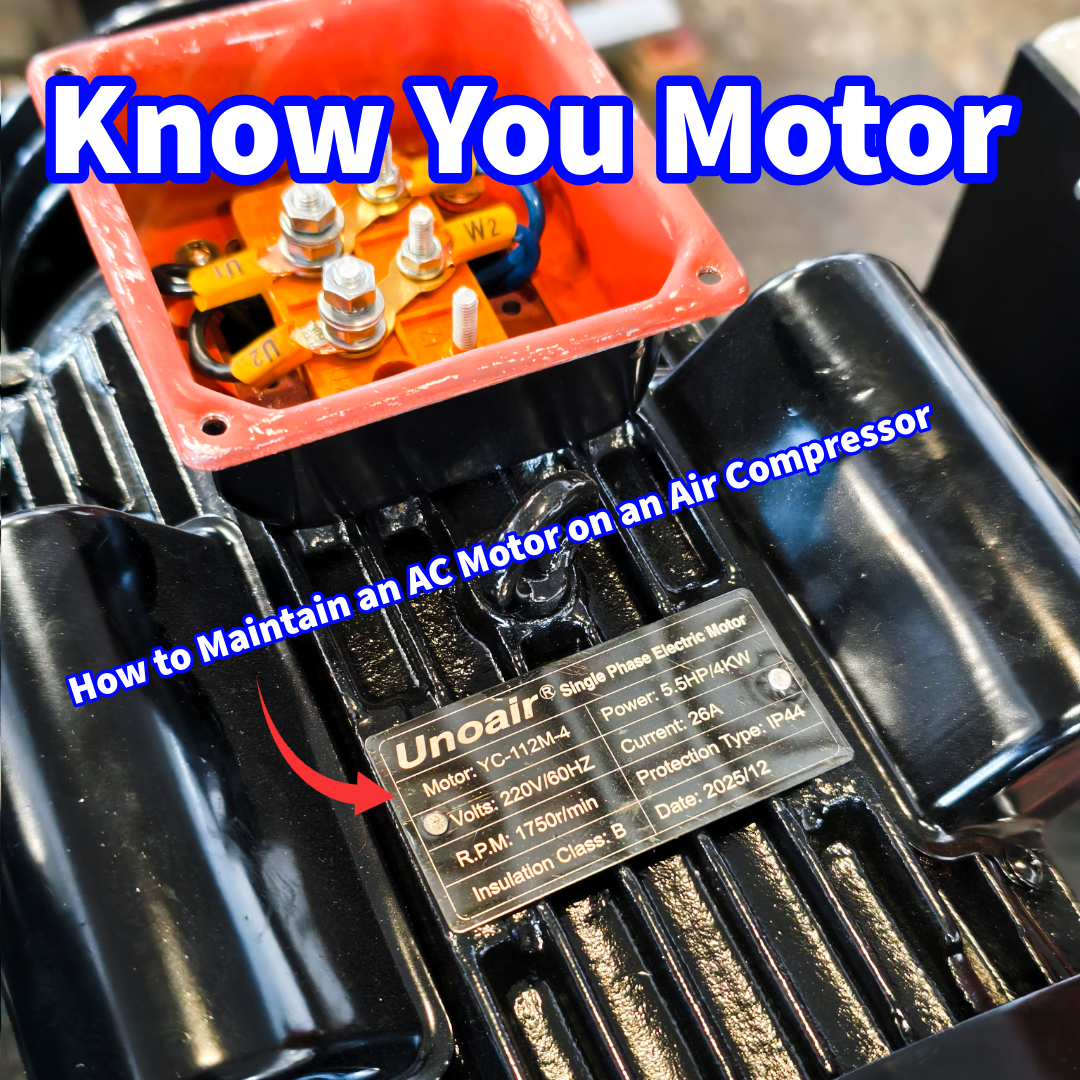

If your air compressor runs on an AC motor, this is a guide to show you how to keep the motor nice and efficient.

1. Daily / Regular Checks

*Keep it clean

Wipe off dust, oil, and dirt. Make sure the cooling vents are not blocked.

*Listen while running

Watch for unusual noise, vibration, or smell. Stop the machine if anything seems abnormal.

2. Weekly / Monthly Checks

*Check electrical connections

Make sure cables and terminals are tight and not damaged or burnt.

*Check motor temperature

The motor should feel warm, not extremely hot.

Overheating means something is wrong.

*Check mounting and alignment

Ensure the motor pulley is firmly mounted and properly aligned with the compressor pump's pulley.

3. Periodic Maintenance

Lubricate if required. Replace bearings if you hear grinding or whining noises.

Confirm voltage and frequency match the motor nameplate.

4. Safety Reminder

Always turn off and lock out power before inspecting or servicing the motor.

Regular checks help prevent breakdowns, improve efficiency, and extend motor life.

For Those Performing Grinding and Cutting Work

Special training and certification are legally required in countries such as Japan when performing grinding or cutting work for professional purposes using pneumatic or electric grinders, rotary tools, or sanders.

For DIY or personal use, this training is not mandatory; however, it is strongly recommended to ensure operator safety and proper, efficient tool use.

Safety First!

Is your compressor ready for the cold winter?

A few months ago, a Japanese agricultural equipment trading company asked us to produce OEM air compressors.

We tested one of their current models, and the results were eye-opening:

-

The “2HP” pump actually produced around 1HP.

-

The “39L” air tank measured only about 32L.

In fact, many manufacturers and sellers display inflated specifications to cut costs.

It’s not uncommon to see 1HP labeled as 2HP, or 7.5HP as 10HP.

That’s why some customers ask,

“Why does Unoair’s 3HP compressor outperform others’ 5HP models?”

If you rely on accurate performance, it may be worth measuring your compressor’s actual tank capacity and air output.

We received a lot of interest and inquiries about our tools from many customers!

We will continue working on strengthening our sales channels so that we can deliver our products to customers in Japan more quickly.

Tool Japan ご来場ありがとうございました

今回もたくさんのお客様に弊社工具へ関心をお寄せいただき、多くのお問い合わせをいただきました!

これから国内の皆さまに、より早くお届けできるよう販売ルートの整備に努めてまいります。